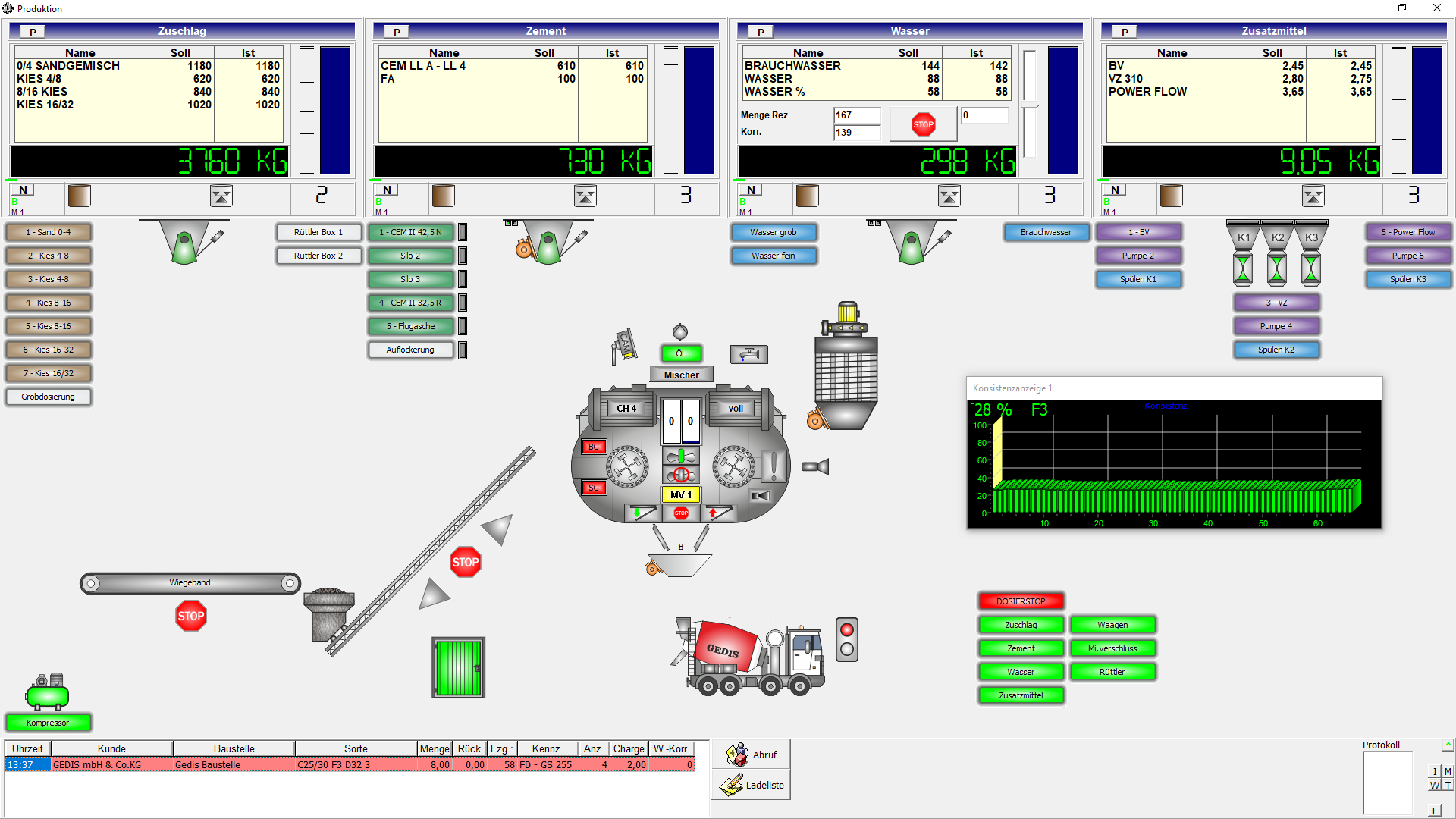

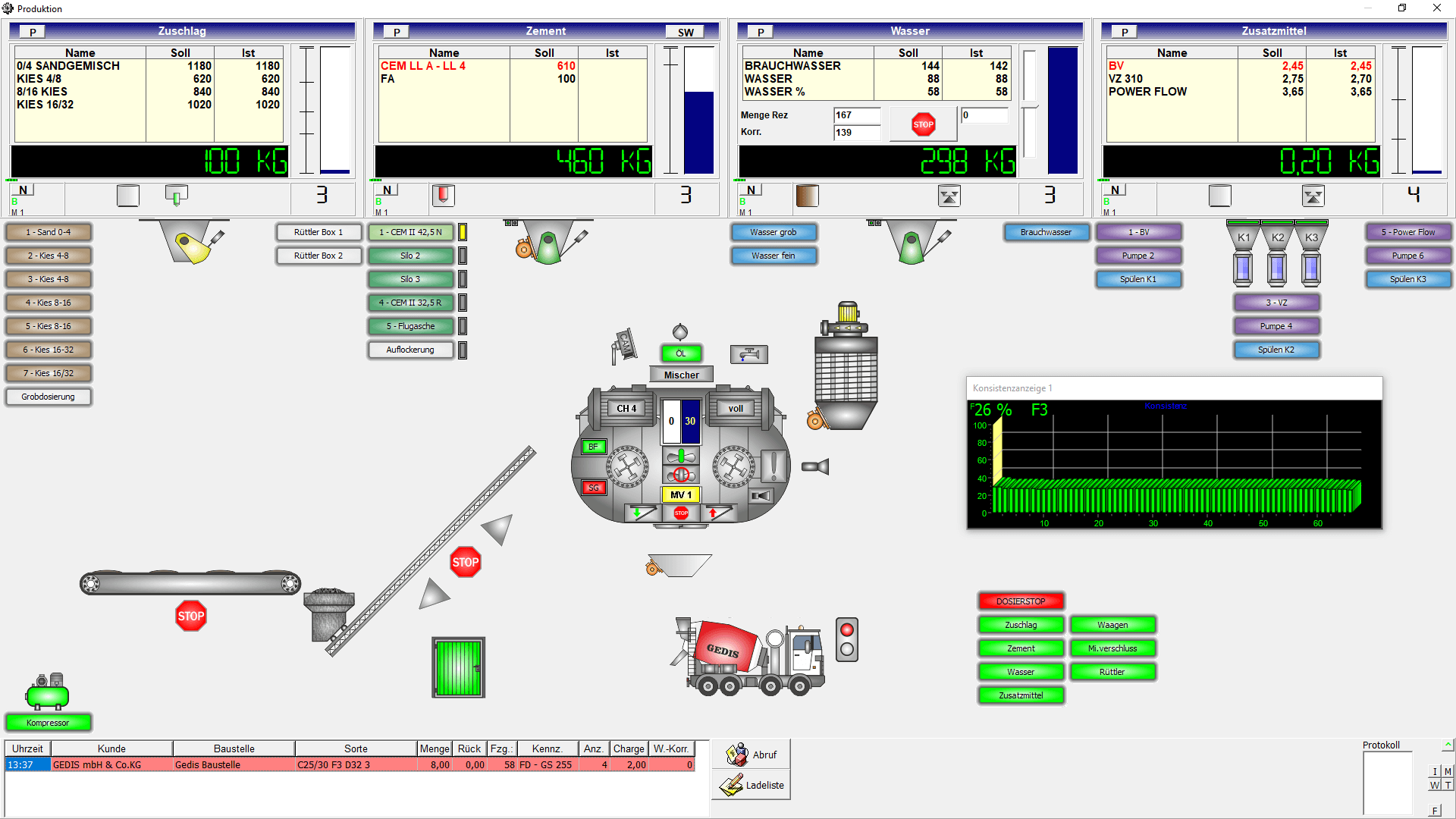

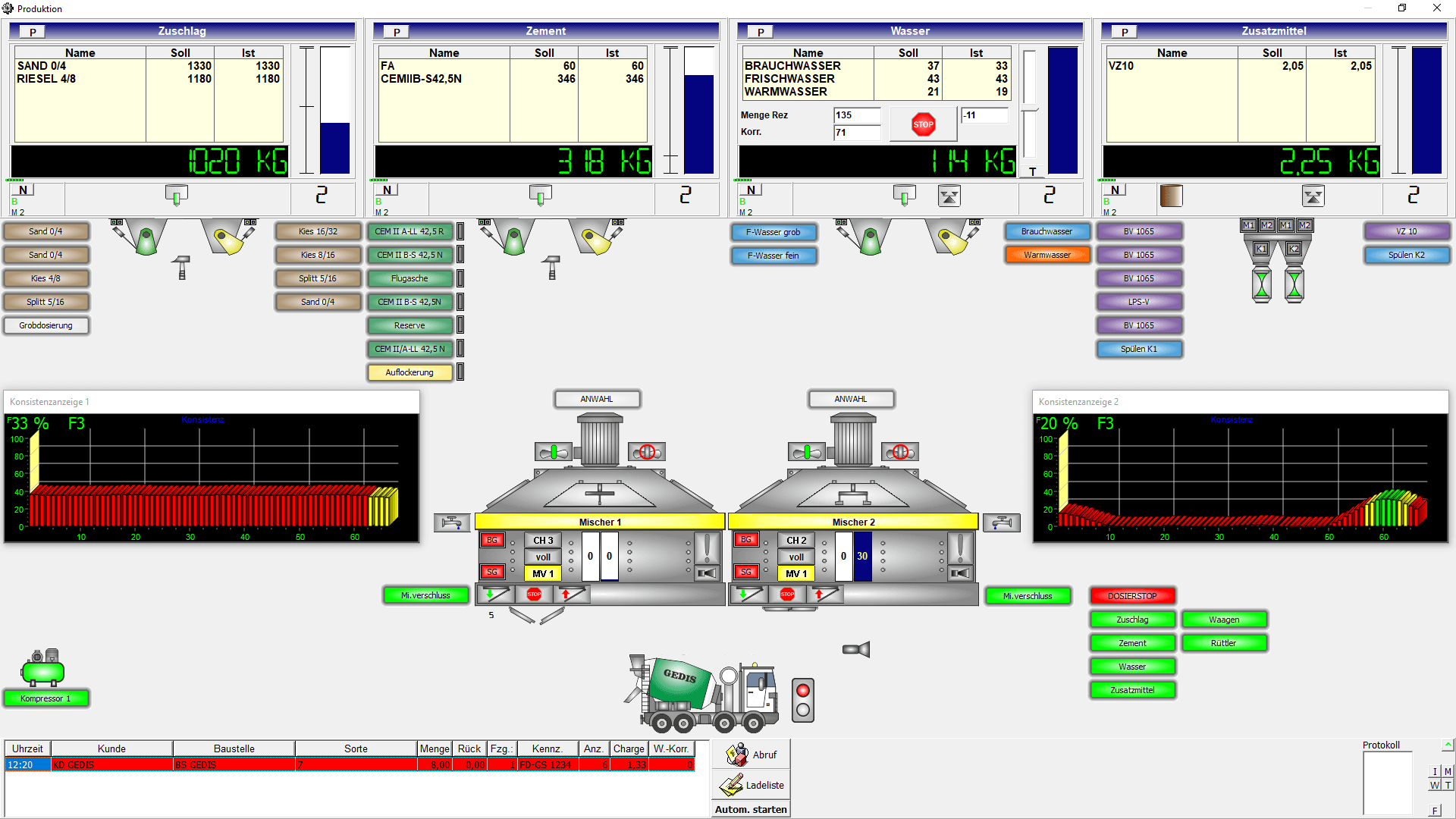

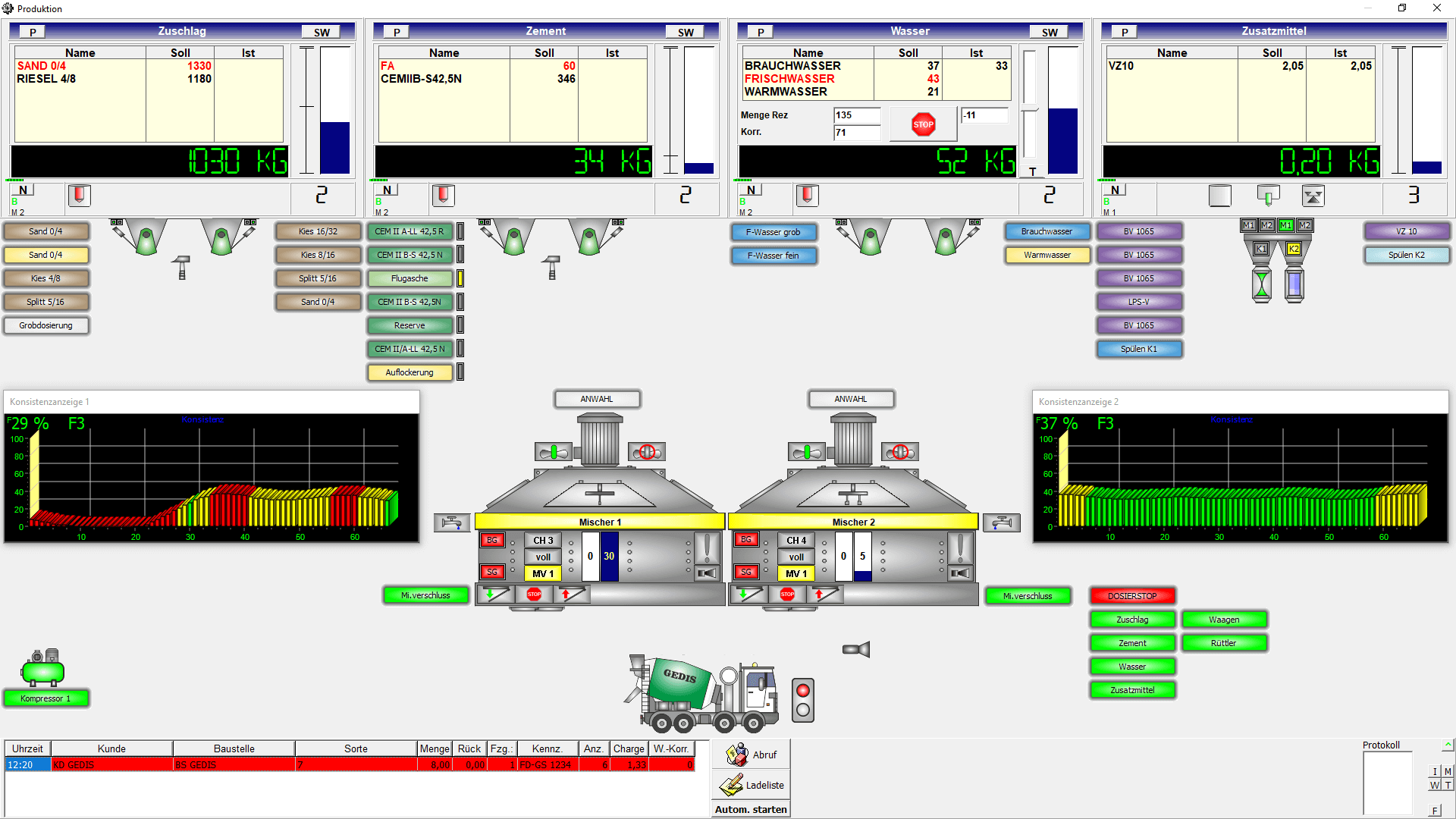

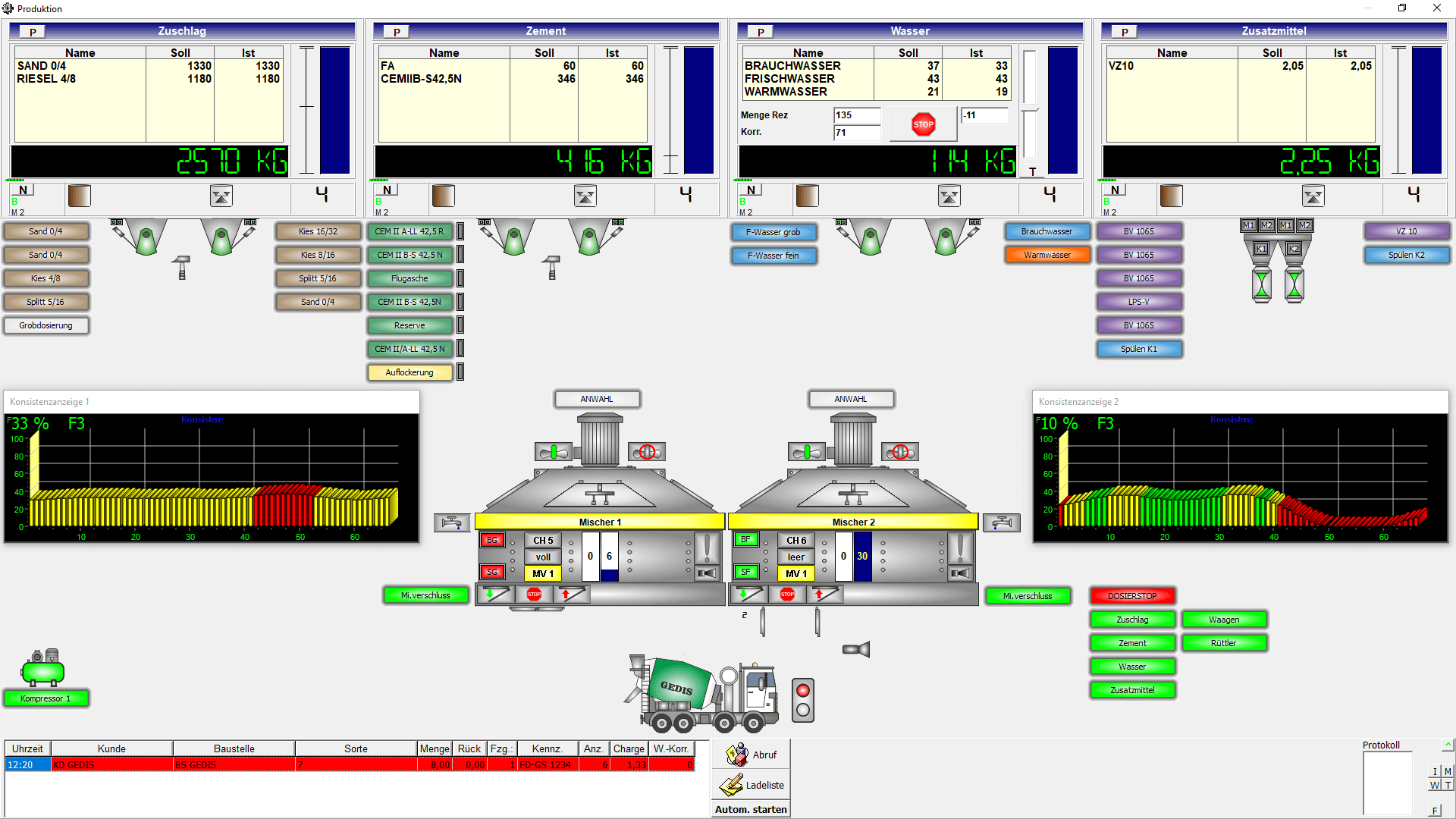

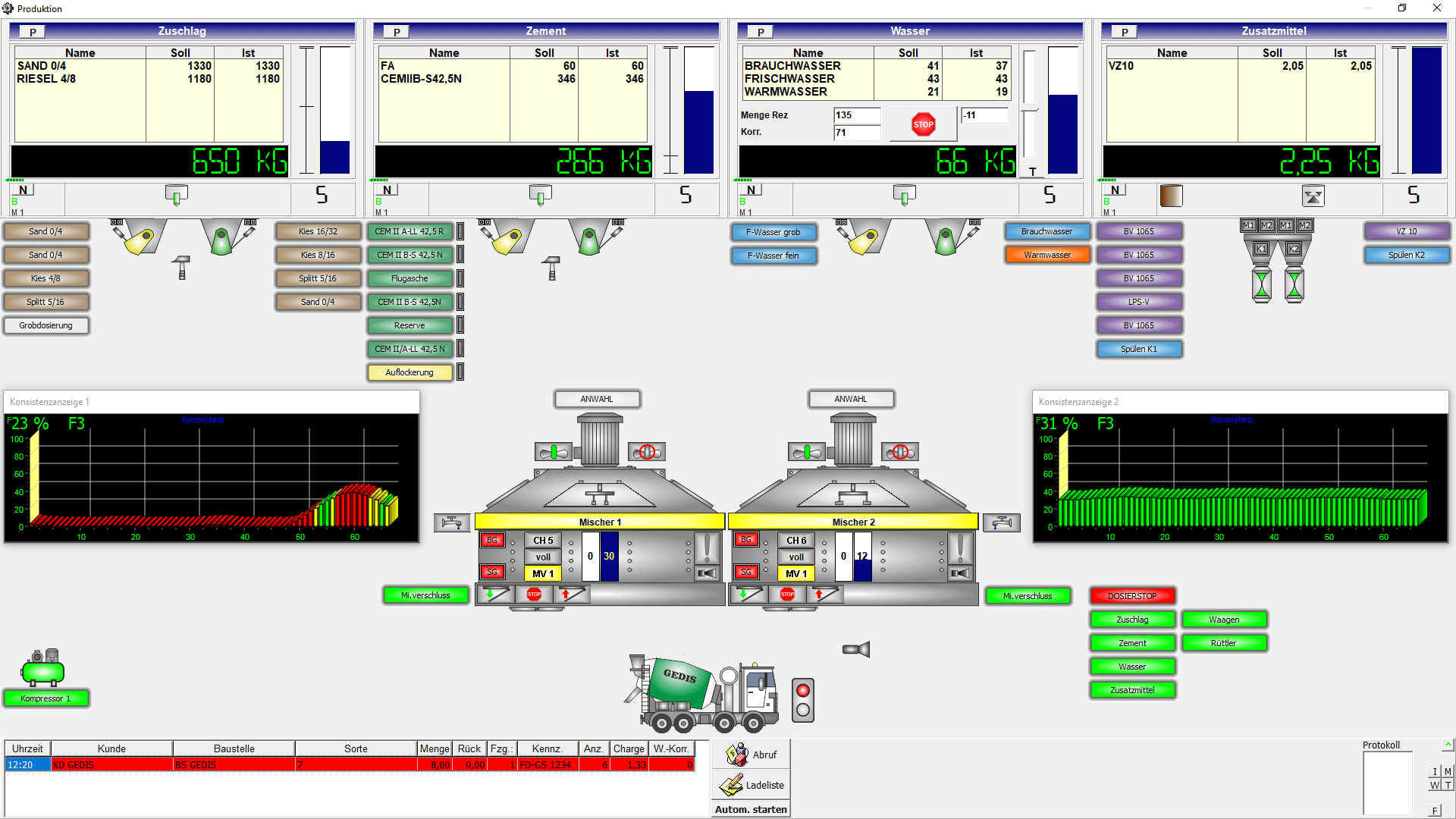

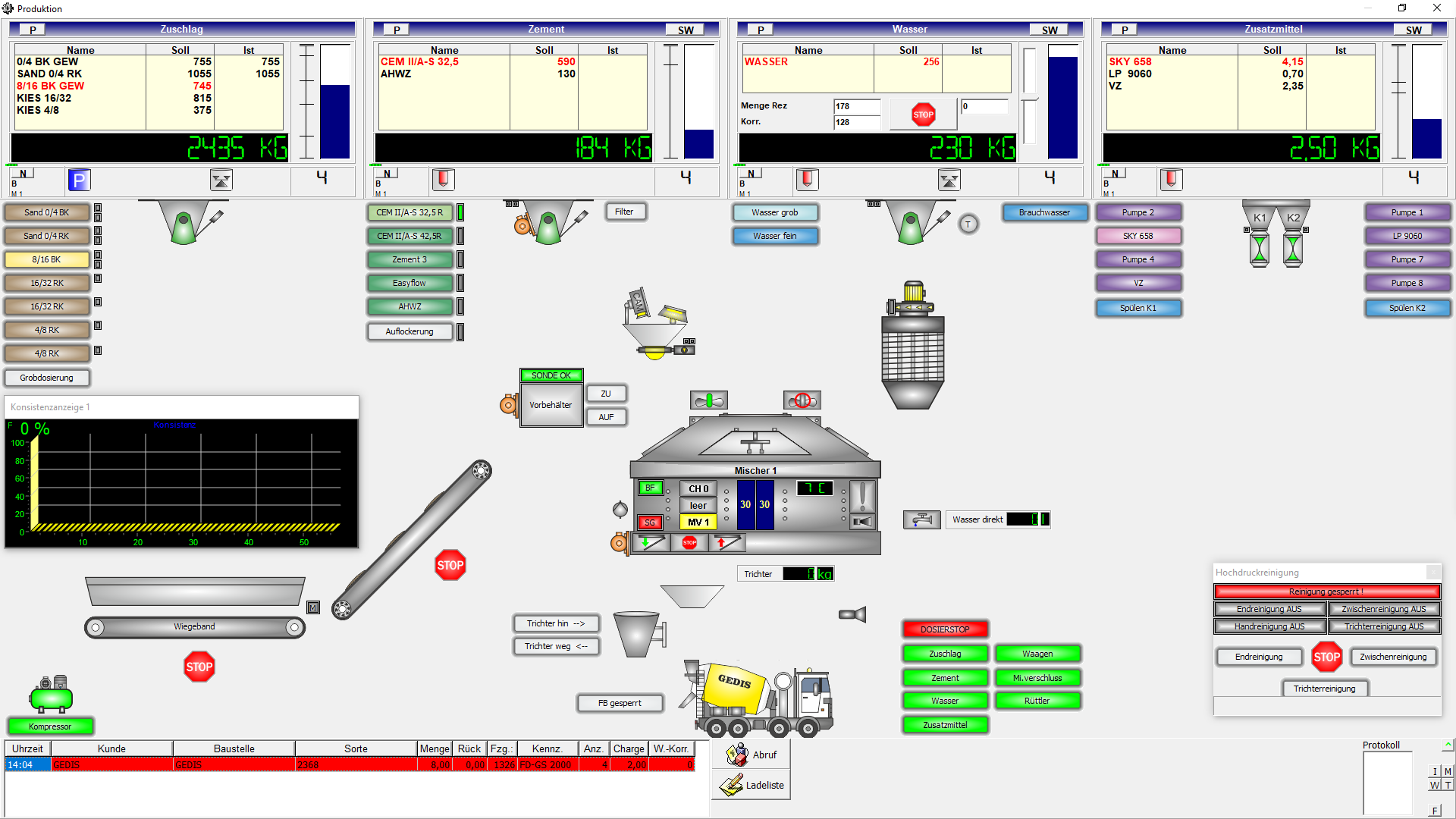

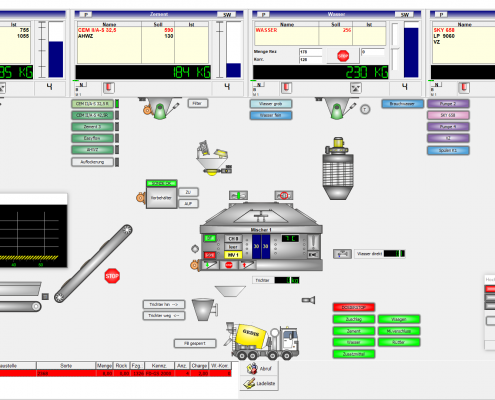

IBS33W control system

The basic version of the IBS33W control system offers a comprehensive software package with a high level of operating convenience. Individual equipment variants and special solutions are possible on request. Based on the market leading Microsoft Windows 10 Professional 64-bit operating system, the IBS33W control system consists of a client application and an SQL database server.

The system is multi-user and multi-client capable and is based on the network functionality of the operating system. Furthermore, the system can be installed in a multi-language version and is UTF8-capable. The software is modular and therefore easy to scale. An integrated release management ensures easy updates.

Horizontal mixing plant

Twin shaft mixer

Inclined belt

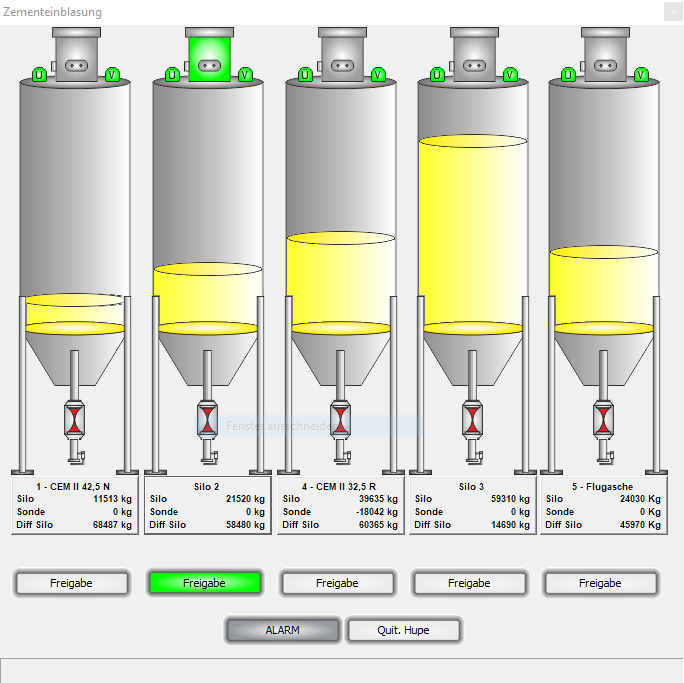

Cement feeding system

In the standard version, the system already contains the following components specifically for you:

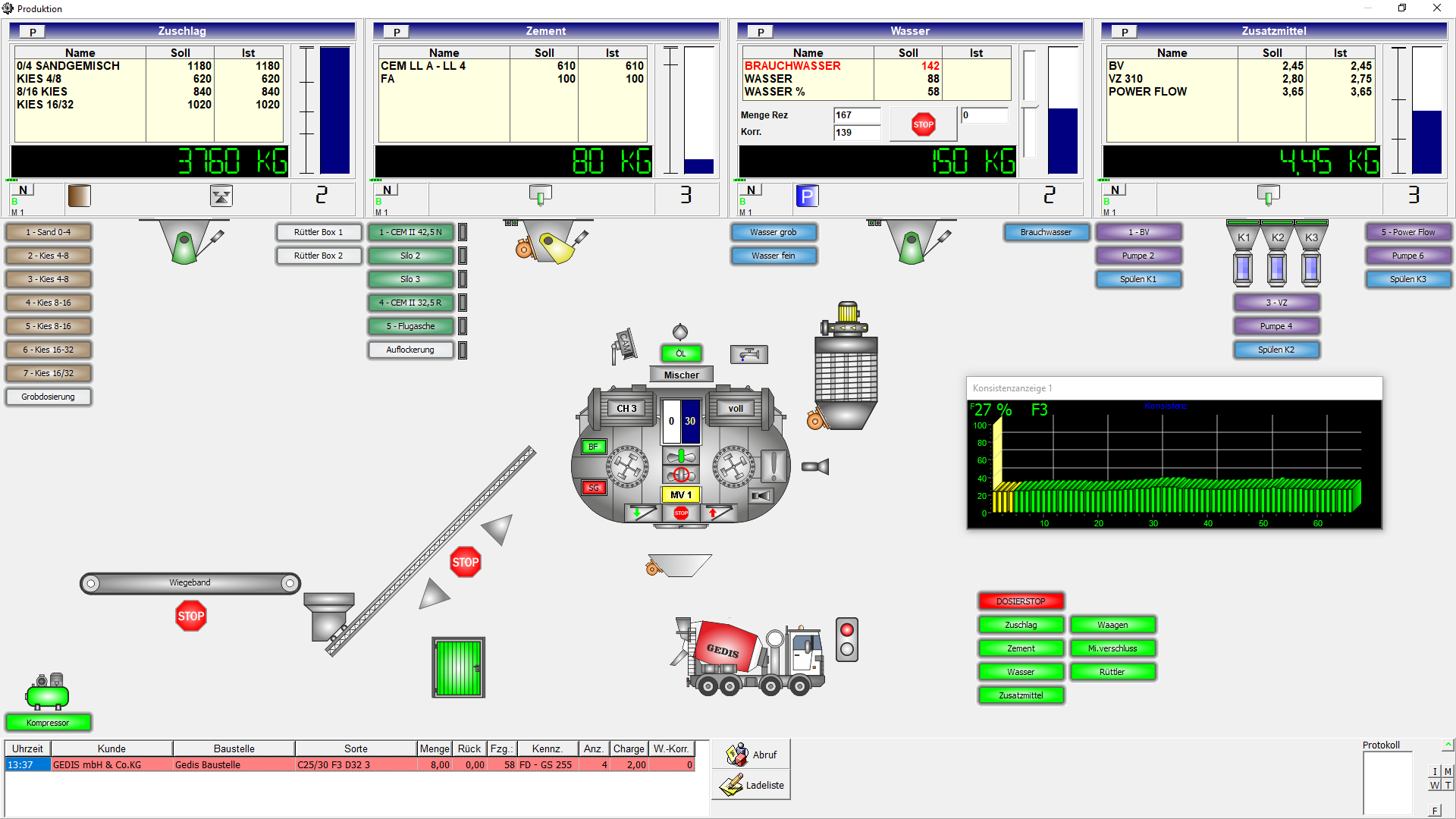

- Dosing system with operating modes, manual and automatic mode

- Autonomous, remote-parameterisable PLC sequence control

- Calibratable weighing amplifier

- Freely programmable system configuration

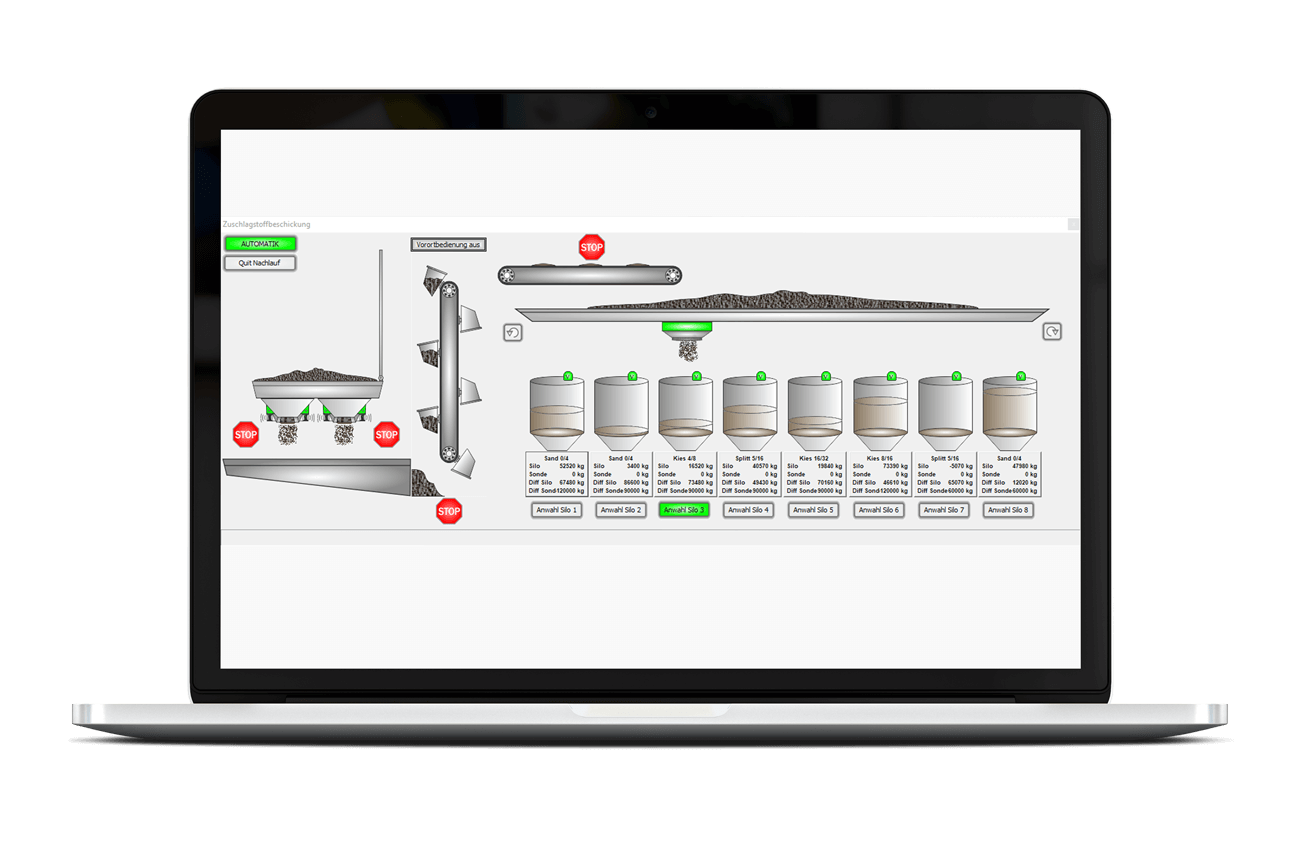

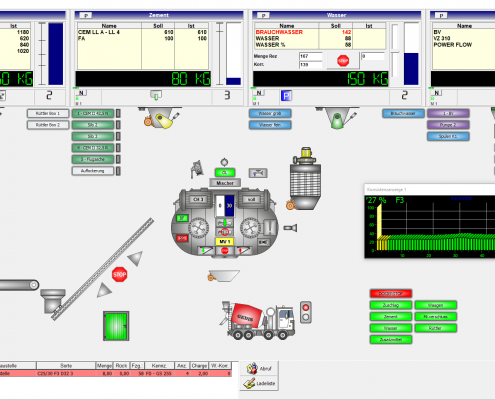

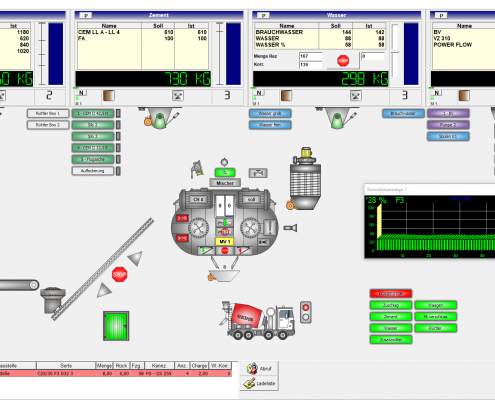

- Process visualisation of all processes

- Order processing, master data and recipe management

- Incoming goods

- Level indicators

- Consistency and moisture measurement

- Actual W/C value measurement inside the mixer

- Outdoor and concrete temperature measurement

- Parameterisable systems and system settings

- Comprehensive statistical evaluations

- Plant optimisation especially regarding consumption

- Delivery note and report printout (editable)

- Data backup (external, internal)

- Remote diagnosis

- Multi-language switchable

- Online help

Do you have any questions?

For services and information contact us using our contact form. Our team will get in contact with you as soon as possible. In urgent cases you can reach us by phone at Tel: +49 661 97380.