RELIABLE and SAFE production with

Control and power unit

The control and power unit is designed and manufactured in-house according to the application based on standardised components and in accordance with the valid guidelines (Machinery Directive 2006 / 42EG, VDE regulations, CE marking) as well as general technical requirements.

More information....

It includes a main switch for overcurrent and under-voltage tripping and also contains all the necessary safety elements for the drives and actuators. Lower maintenance requirements and lower energy costs determine the choice of switching devices for three-phase motors with the perfect starting procedure for the corresponding application. Direct motor start, star-delta starter, soft starter, frequency converter. Quality tested, high quality components offer maximum availability and allow replacement in the event of a fault smooth, fast and cost efficient.

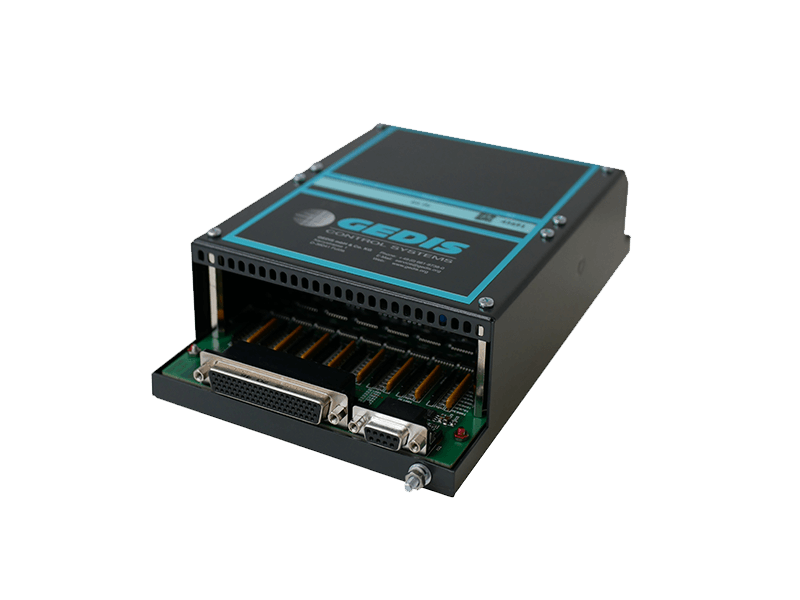

Logic controller (PLC on CAN bus technology)

The programmable logic controller (PLC on CAN bus technology) with a program for monitoring the system in all operating states for the connection to the control and power unit, controls stationary and mobile concrete mixing plants in real time, independently of the master computer.

More information....

The programming of the PLC can be done completely via the screen workstation of the system or by remote maintenance. GEDIS uses robust, intelligent hardware of its own development and production, with separate power supply 24VDC, control processor (Power PC), modules for digital/analogue inputs and outputs, RS232/422/485 interfaces, as well as the worldwide proven, robust and real-time capable CAN bus system. Due to the modular design, the PLC can be adapted and extended to all requirements of the existing system technology at any time. In case of need, a fast exchange of components is possible (MTTR = less than 15min). The PLC is fully functional in its operation, even without a process control computer system, and therefore always in a safe operating state. The PLC monitors itself continuously. Even widely spaced systems can be controlled easily with this from a workstation.

incl. IPC-System (MX1)

This workstation is equipped with a high performance IPC system (MX1). This control computer, which is specially adapted to the general conditions prevailing in the industry, is designed with a hardware configuration ideal for your area of application. The hardware enables safe and stable 24/7 operation, which also allows you to work in shifts in a rough industrial environment. Our innovative hardware also allows equipping a workstation with a specially developed industrial PC “Tank 870”. Accordingly, 6 screens can be operated with a single control computer. In this way interfaces to other systems can be simply and clearly visualised.

MX1

Passively cooled PC system, without fan for industrial and mobile use.

More information....

• Processor Intel Core i5-9500TE 6 x 2,2GHz, max. 3,6 GHz

• an SSD hard drive> = 128 GB (flash memory)

• a second internal hard drive 1TB for data backup

• 16 GByte RAM

• Triple Display (HDMI 1.4, Displayport 1.2, DVI-I)

• CAN Bus Interface

• 6x USB 3.0, 2x USB 2.0

• 1x RS232, 2x RS422/485 (DB9) insulated

• 2x Ethernet RJ45 (GbE Intel l210, l219LM)

• Windows 10 Professional 64Bit

• Temperature range -40 to 70 degrees (with SSD)

• Shock/Vibration IEC60068-2-64 und IEC60068-2-27 (with SSD),

• E-Mark conformity, (ECE) Economic Commission of Europe

• Voltage 9 – 48VDC. (Wide Input Range)

• Mounting kit, power supply, power cord

• Dimensions 268 mm x 246 mm x 108 mm (LxWxH)

• an external hard drive > = 500 GB (anti-shock) for fast data backup, USB 3.0

Tank 870

Passively cooled PC system (Tank), without fan for industrial and mobile use.

More information....

- MX1-D process control computer

- Passively cooled process control computer, for industrial and mobile use,

- Special feature: Extension of the desktop to up to 6 monitors possible.

- MX1-10FEP-D-C246-IF-AC300

- 1x Intel® Core™ i5-9500TE/2.2GHz tray

- 1x Sapphire GPRO 6200/4G

- 2x 8GB SO-DIMM DDR4

- 1x 128 GB SSD SATA-6G 2.5

- 1x WD Black 2.5/1TB

- 1x CAN-PCIeMini/402-2

- 2x CAN-PCIeMini/402-DSUB9

- 6x Mini-Displayport

- Isolation foil

- Windows 10 Pro, Windows 10 LTSC 64 Bit/, Windows 11 Pro

IBS33W with PLC coupling

The control system IBS33W with PLC coupling for controlling the system must be operated near the plant, also from the requirements of the Machinery Directive 2006 / 42EG.

More information....

For the operation and cleaning of the mixing plant, GEDIS uses as the system integrator a high performance, certified safety system with SICK safety PLC with safety function blocks, a key transfer system with safety modules for mixers and safety doors und and a two-handed on-site operation of the mixer within the meaning of the Machinery Directive 2006 / 42EG. Machines upgraded or retrofitted with this technical innovation for occupational safety are safer. The accident risk is minimised and operation is simplified.

Emergency Operation

GEDIS provides an emergency operation at the door of the power unit for the basic functions of the mixer. It is classically integrated, but operates independently safety-locked to the control system IBS33W and serves as redundant safety for emergency discharging of the mixer.

Do you have any questions?

For services and information contact us using our contact form. Our team will get in contact with you as soon as possible. In urgent cases you can reach us by phone at Tel: +49 661 97380.

Contact

GEDIS mbH & Co. KG

Karrystraße 1

36041 Fulda

Phone: +49-661-9738 0

Mail: info@gedis.org